Dimensional Inspection

With J&L’s four highly accurate Coordinate Measuring Machines (CMM), 3DD scanning technology, and highly experienced inspectors, we provide our customers with comprehensive, third-party inspection solutions.

CMM

With J&L’s four highly accurate Coordinate Measuring Machines (CMM), combined with PC-DMIS and Blade software and highly experienced CMM programmers, we provide our customers with comprehensive, third-party inspection solutions.

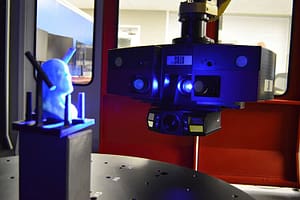

Blue Light Scanning

Structure Blue light scanning provides product data that is crucial to customer success. Our blue light capabilities include:

- Full Rotation MCXL table with integrated ATOS Triple Scan.

- Fanuc Robotic Arm with integrated ATOS Triple Scan and 800mm dia. 360° table.

Data obtained from blue lights scans are accurate to within 5 microns. Our Team of Blue light inspectors offer a wealth of knowledge from part digitization to writing repeatable programs. This allows for quicker repeat inspection that reduces the overall customer lead time. Data obtained from Blue light scanning can be used for:

- Reverse Engineering

- Product Benchmarking

- Quality Inspection

- Additive manufacturing

Manual/Traditional Plate Work

The tried and true method of dimensional inspection remains a staple at J&L. With over 50 years combined experience in plate work inspection, our team of experts will make quick work of any manual inspection job.